|

| |

Bubblers &

Tanks |

| |

|

| The process of Electrolyzing

water has a minimum of two by-products, hydrogen and oxygen gases. As the

gases are made, they rise to the top of the water - in the form of bubbles.

The bubbling action on the surface can be quite turbulent. The turbulence

can cause foam. The foam can collect on the waters surface and get carried

or sucked into the engine. Is that a good thing or a bad thing? Well, a

bubble is a gas trapped inside of a membrane. In our case, it is a water

membrane. If you jump into a lake, you come out wet - right? Well the gases

come out of the hydrogen generator wet. They are trapped inside a thin

membrane of water. Some of the bubbles are big; some are small; some are in

the form of mist; and under certain conditions, they are sometimes in

the form of steam (steam is not a bubble).

As long as the water is pure, the bubbles are not much

of a problem for gasoline engines. Gasoline engines are always burning fuel

mixed with water vapor in the air. They will even run while you pour water

down their throat. Diesel engines are not like that. Water will not compress

into vapor, inside the combustion chamber, thus it will

lockup the piston and damage the engine. Water vapor however will compress

so it is ok. Diesel engines burn water vapor all of the time; it comes from

the air.

One by-product of burning gasoline and diesel fuel is

also water. Both fuels are hydrocarbons. Some by-products of burning carbon

are Carbon Dioxide and Carbon Monoxide. The only by-product of burning

hydrogen is water. So while your engine does not burn water, it sure makes a

lot of it, in the form of steam.

If our engines can handle water vapor, then what is the

big deal about having a bubbler? For the most part, the problem is the other

contents of the water. We add Electrolytes to the water - to increase gas

production. Water is a very poor conductor of electricity - and the

electrolytes change that for us, Chemically. It is the chemicals in the

water that can be destructive to our engines. As the gases rise to the

surface of the electrolyzer, they get trapped inside a water membrane. The

membrane contains the chemicals that are in the water. The bubbles, and the

mist contain traces of the chemicals, That contaminated moisture has the

potential to cause harm to aluminum parts in our engines.

The bubbler's job, in most cases, is to get rid of any

foam. It can also be used to rinse or wash the gases; in other words, get

rid of the chemicals. A bubbler that contains electrolytes can not wash out

or remove electrolytes. To do this, you will need a second bubbler which

does not contain any

electrolytes. I will cover this more, later.

Sometimes a bubbler is used as a Flash Arrestor;

but not reliably. I have witnessed engine backfires that passed from the

intake manifold,

to the bubbler, through the water (from bubble to bubble) and out of the

bubbler to the

electrolyzer. The closer the bubbles are together, the better the chances

for a flashback to make it through the water. HHO is an explosive gas. The

explosion travels faster than a speeding bullet; over 3,000 feet per second.

Don't trust a bubbler to stop a flashback.

|

|

Wet Cell - Water Bath Systems |

Hydrogen generators that do not have sealed off water compartments, between

each set of electrode plates or tubes, are considered water bath systems. In

other words, water can flow or touch all parts of the plates; the bottoms,

the tops, the sides. My tube cell is a prime example; or Joe Cell design as

some want to call it, My tubes are submerged in a container of water. Water

fills the tubes from the bottom and from the top (if I keep the water level

up). I allow 4 to 5 inches of freeboard above the top of the tubes;

freeboard is waterless head space. I use this area to dissipate the foam. By

doing this, I do not need a bubbler; it is built in.

This is an excellent design for cold weather. If and

when the water freezes, the generator can not produce hydrogen and oxygen.

As soon as the water starts to thaw, the generator is safe to use. I only

have one hose on the generator; it is at the top of the water free space,

above the frozen water.

I could use a Bubbler as a Scrubber to wash or filter

electrolytes from the gasses. But by doing so, I would risk the safety of a

frozen generator. I do not have a problem with foam, so I choose not to use

a bubbler.

If you use a stainless steel container with tubes, for your water

bath system, you will not have to worry about your system breaking or

cracking when it freezes. At most, it will just push the hose off of the

lid. A tube stainless steel water bath system is by far the safest hydrogen

generator. It is also the most expensive to build.

|

|

Dry Cell Systems |

Hydrogen generators that have sealed off water compartments, between each

set of electrode plates or tubes, are considered dry cell systems. In other

words, water can not flow or touch all parts of the plates. The bottoms, the

tops, the sides are all sealed off so that water can not get past them. Each

set of plates forms a water tight compartment.

There is very little head space, if any. A lot of foam is produced and it

has no place to accumulate, so it gets pushed or pulled out of the

generator.

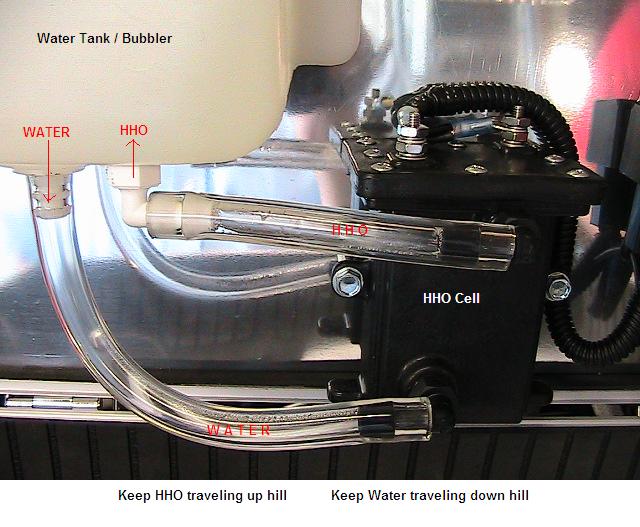

This system is going to need a Bubbler. The bubbler

can also be used to re-supply water to the Dry Cell. That would make it both

a bubbler and a tank. By installing the bubbler/tank above the Dry Cell,

water will circulate and help cool the generator.

Another option would be to use a separate Tank to

refill the Dry Cell, and use a Bubbler to wash/scrub the gases. If you do

this, you loose the cooling circulation. If you want the circulation, then

you will have to use a pump to keep the water circulating between the Tank

and the generator. In order to use the Bubbler as a washer, the hose from

the generator to the Bubbler needs to be- above the water line. It can then

be extended below the surface of the water. If you connect that hose at the

bottom of the bubbler, the water in the bubbler will mix with the water in

the generator. The water in the generator contains electrolytes. The water

in the bubbler does not.

A Dry Cell is disadvantaged when it comes to winter

driving. The main reason is the Bubbler. If the water in the bubbler

freezes, the water lines also freeze. The cell can not be operated safely

until ALL of the lines thaw. If the generator thaws out before the water

lines thaw, and you turn it on, the gases will build up pressure. If they

can not find an escape rout, they can self ignite under pressure.

A Dry Cell System is the most efficient electrolyzer

design. It is most popular built using flat plates, but it can be built

using tubes.

|

|

Caution Tips |

- Never assume the Lid on the Bubbler is sealed. Imperfections may

exist with the Tank, the Gasket, or the Lid. Give it a Blow Test. It is simple.

Tighten the Lid, stop-up all of the hose fittings - but one; blow

constant pressure into the tank via the one hose fitting. If there is a

leak, you will know it. That is, unless you blow like a blond (no pun

intended women). Do it like you are trying to blow up a balloon, not

blowing out a candle.

- Perform the Blow Test on the complete system; from the cell exit

hose, all the way to the engine input. If it will not hold pressure,

there is a leak. Hydrogen will find the slightest leak.

- Always test for HHO output where it enters the engine. Remove the

hose from the engine input and place it in a container of water. Bubbles

should be present when the HHO generator is operating.

|

| |

|

|

Tanks |

|

US Plastics US Plastics

Flambeau Fluid Systems will custom make products for you - if you order in

quantities.

Flambeau Fluid Systems will custom make products for you - if you order in

quantities.

|

|

More Tanks |

|

Tanks with 12v and 24v

Pumps Flambeau Fluid Systems will custom

make products for you - if you order in quantities.

Pump tanks

Pump tanks

Just Pumps

Just Pumps

|

|

Lids |

|

US Plastics Caps -

Un-vented, Heavy Duty US Plastics Caps -

Un-vented, Heavy Duty

Flambeau Caps Flambeau Caps

|

|

Misc. Parts |

|

US

Plastics US

Plastics

Many types

available at Flambeau Fluid Systems Many types

available at Flambeau Fluid Systems |

|

|

|

|

|

|

McMaster-Carr Tube Fittings

McMaster-Carr Tube Fittings |

|

|

|

|

|

|

|

|

|

|

Heavy Duty Bubbler / Scrubber / with Flash Port

* 19 inches Tall

* 4 inches Wide

* 3/8 inch Barbs

Available from

GreenFuelH2O Available from

GreenFuelH2O |

|

|

|

|

Flash Port

Flash Port

Available from

GreenFuelH2O Available from

GreenFuelH2O |

|

|

Screen Strainers |

|

Removable Neck Strainers; available in 2

sizes

Flambeau

Flambeau |

|

Water Level Sensors |

|

Level Sensors

Flambeau

Flambeau |

|

Tubing |

|

Masterkeeper Clear PVC Tubing

(thick)

http://www.mcmaster.com/#standard-pvc-tubing/=tcj18w |

|

|

US Plastics Tubing

US Plastics Tubing

Excellent physical and electrical properties. Wide range of working

temp. -100°F to 400°F. Fluorinated ethylene propylene (FEP) is a

chemically inert thermoplastic. Transparent tubing is excellent for

acids (all concentrations), aliphatic alcohols, aldehydes, bases,

esters, hydrocarbons (aliphatic, aromatic and halogenated), ketones and

strong oxidizing agents. Can be rigorously cleaned in boiling nitric

acid for high-purity analysis. |

|

|

|

Tygon® Inert

Tubing SE - 200 Tygon® Inert

Tubing SE - 200Tygon® Inert

Tubing can handle many applications where flexible tubing of the past

could not be used. It’s FEP inner inert, meaning it will not extract or

contaminate fluids being transferred, liner provides the ultimate in

chemical resistance and can handle a wide variety of fluids from

corrosives to MEK-based solvents. The fluid path will not impart odor or

taste, making it well-suited for food and beverage use. It meets FDA

criteria for food and beverage applications, as well as USP Class VI

criteria for biocompatibility. Use single barb insert fittings. Max

working temp 170°F.

|

| |

|

|

Clear Reinforced

Tubing. Comes in 3/8 inch I.D and larger. Available at Lowe's home supply

stores. |

Page Last Edited -

04/03/2022

|