| Electrons

moving across a conductor produce heat from friction. Our goal,

using electrolysis of water, is to minimize the heat produced by the electrodes.

It makes no difference if they are plates, tubes, rods, screws, bolts, wire, etc.

They all produce heat when electrical current passes across them. With

that in mind, I am going to explain how to determine the amperage saturation

point of your Cells; the maximum amount of amperage the electrodes can

support "continuously" without causing excess heat. The late great

Michael Faraday teaches us that each square inch of electrode surface,

can "efficiently" pass 0.54 amps of electrical current. We label that as Current Density;

the amount of amperage an electrode can carry or distribute, without

causing excess heat. It is the maximum amperage that should be used. If we follow that rule, our electrodes

will not deteriorate from electron bombardment (for the most part), and

they will operate continuously without overheating and causing steam.

In theory, Electron flow is around and down the Negative

power wire, and onto the electrical connection of the negative

electrode. From their, electrons take the path of least resistance. They are attracted to the Positive electrical pressure coming from the

positive power source across the water - in our Cell. The pressure

must be great enough to be felt across the water and any obstacles along

the way (other electrodes and the water between them).

Ok, let's back up and look closely at the Negative electrode, and

lets call it a plate. Depending on where the electrons hop onto the

plate, they travel from there, across the surface, around the sides, and

on to the opposite side - where attraction is strongest. And guess where

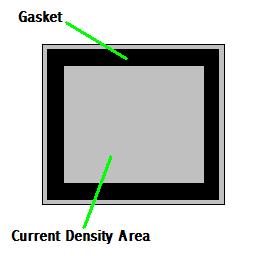

attraction is strongest. It is strongest inside

the gasket area that touches the water. That area inside of the

gasket is smaller than the entire surface area of that side of the plate.

Thus, the gasket funnels the amperage into using a smaller area. Example: I have a

4x4 inch square plate. I am using a 3.75 inch O-Ring gasket that

is 1/4 inch thick and has an inside diameter of 3.5 inches. The 4x4 inch

plate contains 16 square inches of surface area, on one side. The inside

diameter of the O-Ring has 12.25 square inches. If I use the dimensions

of the plate to calculate Current Density, the plate can efficiently

distribute 8.4 amps. All of that amperage has to pass through the

O-Ring, which by the way can only distribute 6.615 amps efficiently.

Amperage flow is going to be restricted in that smaller area. Electrons

are going to accumulate, pile up, and that is going to cause excessive

heat.

So in my opinion, for what it is worth, Current Density calculations

must be based on the dimensions of the inside area of the gasket; the

location where electrons congregate to cross the water. This is

totally disregarded by everyone; yet it is so clear to me. I did not

recognize it until I started building my Cell Configurator. And that is

why my Configurator asks for the size of the Active Surface area of the

plate, not the size of the plate. It wants to calculate the current

density of the inside area of the gaskets; because that is where Current

Density matters most; that is where it is restricted the most. Electrons

travel across the plate and are then funneled to a smaller surface area

from which they exit the plate and cross the water. From there, the

journey continues from plate to plate, in the same sequence. Electrons

travel from inside the O-Ring, across the water to the inside of the

next O-Ring, around the plate to the opposite side, out that O-Ring and

across the water. They continue this process until they reach the

Positive electrical connection. That is the downfall of a Dry Cell. If

we were using Wet Cells, Current Density would be based on the plate dimensions.

If you are still confused, look at it this way. If I pass amperage

down a 2 inch diameter wire and reduce the size to a 1.5 inch diameter

wire, the 1.5 inch wire will get hot sooner. Will it not?

Now with all I have stated above, "What do you think about companies

that add up the Total Square Inch surface of a plate, Front, Back, and

Sides, then they multiply that times the number of plates and use that

total to calculate how much amperage their Cells can operate on"; there

are a lot of them. "What do you think about companies that use the

Square Inch of one side of a plate and multiply that times the number of

plates to get a total sq. in. to calculate with?" There are a lot of

them. Now "what do you think about companies that use the sq.

in.

of one side of one plate and multiply it by the number of water

compartments to calculate their maximum amperage?" They are

few and far apart. I am providing this information to expose the lack of

technical knowledge most of these Companies Have. They take too

much

for granted because they mostly copy someone else's work, or they make things sound good.

To my knowledge, Global Ecological Solutions is

the only company accurately calculating Current Density. I

know of at least one company that bases Cell efficiency on MMW

calculations. Well excuse me, but MMW calculations are for a specific

time period - of a specific test. MMW has nothing to do with the Maximum

Amperage a cell should be operated at "Continuously". Do you want a Cell

that runs cool for 30 minutes, or one that runs cool for 30 hours.

Current Density calculations are an important part of the formula. It

should not be overlooked. To my knowledge, Global Ecological Solutions is

the only company accurately calculating Current Density. I

know of at least one company that bases Cell efficiency on MMW

calculations. Well excuse me, but MMW calculations are for a specific

time period - of a specific test. MMW has nothing to do with the Maximum

Amperage a cell should be operated at "Continuously". Do you want a Cell

that runs cool for 30 minutes, or one that runs cool for 30 hours.

Current Density calculations are an important part of the formula. It

should not be overlooked.

There is one more observation I would like to make aware, and that is

the edges of the electrodes plates. Electrons are not good at making

sharp turns. Our Wet Cells are considered inferior to Dry Cells, because

electron flow can leak across the water by flying off of the edges of the plates.

The conductivity of the water makes it possible. I discovered, a long time

ago, that it can be eliminated by rounding off the sharp edges of the

plates. Electrons will then make the turn easier, and cell efficiency increases.

Hope this Helps.

David Biggs

mailto:david@hho4free.com

|