|

|

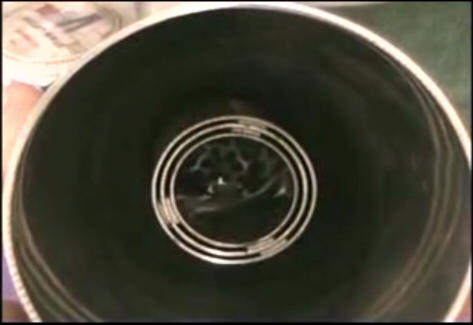

This is my best cell configuration. I am using 3

tubes inside the container. They are made of very low magnetic 304 stainless

steel.

-

1.5 inch cathode - 0.065 thickness

-

1.75 inch neutral - 0.065 thickness

-

2.0 inch positive - 0.065 thickness

-

4 inch container with a hole drilled in the bottom for the

cathode bolt. 0.083 thickness. A 3 inch container would work just as well.

-

Spacing between the tubes is 0.060 about 1/16th inch

|

|

The tubes are held

together by spacers I made from a Poly cutting board. I cut the spacers

0.058 to 0.060 thickness. The tubes are held

together by spacers I made from a Poly cutting board. I cut the spacers

0.058 to 0.060 thickness. |

| |

|

Turning the tubes on

end will make it easier to work with. Turning the tubes on

end will make it easier to work with.You are going to insert 3 spacers

about 120 degrees apart. Don't measure it, just eyeball it. |

| |

|

You will need a pair

of needle nose pliers to squeeze the tubes closer together so as to make

room for the 3rd spacer. You will need a pair

of needle nose pliers to squeeze the tubes closer together so as to make

room for the 3rd spacer. |

| |

|

Put 2 spacer in and

hold pressure on them so they don't drop down inside the tube. To get the

3rd spacer in, you will need to squeeze the tubes between those two spacers.

This provides just enough room for the 3rd spacer. If it is not a tight

fight, the tubes will slide out of place while you are driving down bumpy

roads. Put 2 spacer in and

hold pressure on them so they don't drop down inside the tube. To get the

3rd spacer in, you will need to squeeze the tubes between those two spacers.

This provides just enough room for the 3rd spacer. If it is not a tight

fight, the tubes will slide out of place while you are driving down bumpy

roads. |

| |

|

You can see that it

makes a nice neat job if you align the insulators the same. You can see that it

makes a nice neat job if you align the insulators the same.Use a small

hammer to tap the insulators down even with the tube surface.

Notice the perforated flat plate that has been cut to fit and welded just

inside the tube. Flat plate would work. |

| |

|

It is very critical

for the tubes to be equally spaced apart, from top to bottom. Surfaces that

are closer will produce more HHO than surfaces farther apart. Take your time

and get this step right. It is very critical

for the tubes to be equally spaced apart, from top to bottom. Surfaces that

are closer will produce more HHO than surfaces farther apart. Take your time

and get this step right. |

| |

|

Now that the tubes

are assembled to the cathode, it is time to insulate the cathode bolt from

the container. This particular container is a joecell setup. The bolt goes

out the bottom. You could easily use a solid bottom, and take the bolt out

the top of the cell - through the lid. More on that later. Now that the tubes

are assembled to the cathode, it is time to insulate the cathode bolt from

the container. This particular container is a joecell setup. The bolt goes

out the bottom. You could easily use a solid bottom, and take the bolt out

the top of the cell - through the lid. More on that later. |

| |

I made two

insulators out of cutting board material. The inside one is tightly threaded

onto the bolt to keep water from leaking between the threads. Notice the nut

and washer are used to keep the tubes off of the bottom. I made two

insulators out of cutting board material. The inside one is tightly threaded

onto the bolt to keep water from leaking between the threads. Notice the nut

and washer are used to keep the tubes off of the bottom.The lower

insulator is grooved for an O-ring |

| |

Make sure the

insulators lip goes inside the hole. It keeps the bolt from touching the

container. Make sure the

insulators lip goes inside the hole. It keeps the bolt from touching the

container. |

| |

|

Keep a firm grip on

the tube assembly as you tighten the nut. Don't let it slip. Take your time.

Keep the tubes straight up and down. Keep a firm grip on

the tube assembly as you tighten the nut. Don't let it slip. Take your time.

Keep the tubes straight up and down.We now have our cathode ready for the

Negative voltage. |

| |

|

The cell is ready

for a positive connector. Positive must be applied near the top of the outer

tube, the 2 inch-er. The cell is ready

for a positive connector. Positive must be applied near the top of the outer

tube, the 2 inch-er.You could weld or bolt a threaded rod to that tube

and take it out the side, or the lid.

I am doing something different.

|

| |

|

I plan to

experiment with the number of tubes. To make it convenient, I will make the

container positive and short it to the closest tube. I cut some wedges out

of a 2 inch tube. |

| |

|

I bent the

wedges and forced them between the container wall and the tube wall. This

helps stabilize the top of the tubes. The connection needs to be very tight. I bent the

wedges and forced them between the container wall and the tube wall. This

helps stabilize the top of the tubes. The connection needs to be very tight. |

| |

|

The insulators have a

lip that fits into the hole in the bottom of the container. The insulators have a

lip that fits into the hole in the bottom of the container. |

| |

The lip needs to be a

little taller than the O-ring. The lip needs to be a

little taller than the O-ring. |