|

| |

|

Cell Stacks |

|

|

|

Current Density |

MMW |

Neutral Plates |

Number of Plates |

Plate Configurations |

Voltage & Amperage

|

It has been

brought to my attention that confusion exists, among experimenters,

about what a Stack of cell plates is and when and why multiple stacks are used. I

will attempt to explain it for you and provide some pros and cons for

using them.

|

|

I will be analyzing cell stack efficiency

and explaining the reasons for additional

neutral plates, additional

stacks, and what they accomplish. Cell Stacks is another topic that no one seems to

explain; yet most companies incorporate multiple stacks into their

cells. For what it is worth, the following is My opinion; my inside view of the process.

What is a cell stack?

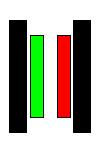

Basically, a water "Cell Stack" is a group of electrodes consisting of a positive and a

negative, and any number of neutral electrodes between them.

For instance ( + - ) consists of a positive electrode and a

negative electrode. Together, they create a single water compartment

between them. We call that a "Cell". ( + n - ) consists of one neutral between positive

and negative. One neutral creates 2 water compartments between positive

and negative. ( + n n n - ) consists of 3 neutrals between positive and

negative. 3 neutrals create 4 water compartments between positive and

negative. Each water compartment is considered a "Cell" and a group of

cells is considered a "Cell Stack".

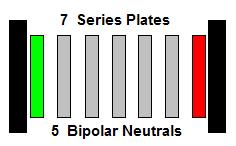

The most popular cell configuration for 12 volt systems is 7

plates in Series. It consists of 5 neutral plates separated by a

single positive and a single negative electrode (a cell stack). Its

configuration looks like this ( + n n n n n - ). The 7 plates create 6

water compartments between the positive and the negative plates; count

them. Each of those water compartments creates a Voltage Drop that can

be individually measured. That voltage drop will be equal to the voltage

source divided by the number of water compartments. If 12 vdc is applied

to positive and negative, the voltage dropped across each water

compartment will be 2 volts; do the math --- 12 vdc divided by 6 water

compartments =

2.vdc. 7 plates in series is capable of producing 1 LPM @ 16 amps. The

late great Michael Faraday tells us that each water compartment can

produce 10.44 ML PM of HHO, per amp. 10.44 x 6 = 62.64 x 16 = 1002.24

ML PM.

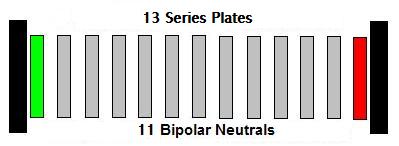

The most popular cell configuration for 24 volt systems is 13

plates in Series. It consists of 11 neutral plates separated by a

single positive and a single negative electrode (a stack). Its

configuration looks like this ( + n n n n n n n n n n n - ). The 13

plates create 12 water compartments between the positive and the

negative plates; count them. Each of those water compartments creates a

Voltage Drop that can be individually measured. That voltage drop will

be equal to the voltage source divided by the number of water

compartments. If 24 vdc is applied to positive and negative, the voltage

dropped across each water compartment will be 2 volts; do the math ---

24 vdc divided by 12 water compartments = 2.vdc. 13 plates in series is capable of

producing 1 LPM @ 8 amps. The late great Michael Faraday tells us that

each water compartment can produce 10.44 ML PM of HHO, per amp. 10.44

x 12 = 125.28 x 8 = 1002.24 ML PM.

Have you noticed that higher voltage requires more plates and uses

less amperage to produce more HHO gas?

|

Multiple

Cell Stacks

Generally speaking, we recognize a group of electrodes as a "Cell". We

usually do not include the word "Stack". I think that is what causes the

confusion when we have multiple groups of Cells sharing the same

positive or negative electrode. For instance:

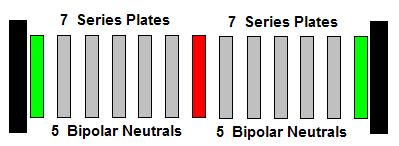

- 2 Cell Stacks would look like this ( + - + ). Each cell stack is

sharing the same negative electrode.

- 2 Cell Stacks could also look like this ( - n n + n n - ). Each

cell stack is sharing the same positive electrode. Or (+ n n - n n +

). Each cell stack is sharing the same negative electrode.

- 3 Cell Stacks could look like this (+ - + - ) or this ( - n n n +

n n n - n n n + ). Each cell stack is sharing either a positive or a

negative electrode.

|

Why use Multiple Cell Stacks?

This is where it gets complicated. In the examples above, I stated that

the most popular 12 vdc system uses 7 plates in Series. It is popular

because it is proven to be a very efficient configuration. It is capable

of producing 1 LPM @ 16 amps; compared to a 6 plate cell stack that

would only produce 835 MLPM @ 16 amps. Plus, 7 plates lowers plate

voltage to around 2 vdc, where as 6 plates would lower voltage to around

2.4 vdc. The lower 2 volt plate voltage allows the cell stack to operate

continuously for longer periods of time than the 6 plates 2.40 vdc,

because it produces less heat; about 40% less. If it produces 40% less

heat, then it can operate 40% longer --- while producing 1 LPM.

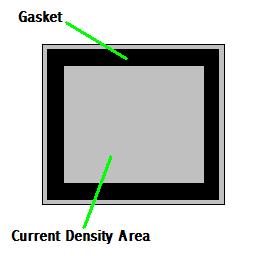

The catch to this is the size of the plates. The plates require

enough Active Surface Area to distribute 16 amps without causing

overheating. The late great Michael Faraday tells us that 1 square inch

of surface area can distribute 0.54 amps. According to my calculations,

16 amps would require about 30 sq. inches. That equates to a surface of

about 5.5 x 5.5 square. That is the size requirement "between" the plate

gasket, not the size of the plate. To accomplish this, the plates would

need to be 6 to 6.5 inches square.

Now tell me, how many cells have you seen advertised with 4 inch

plates? Cells that can produce 1 LPM or more? How can they do it, when 7

plates is about the maximum that can reasonably be used without

introducing excess heat? The answer is "Multiple Cell Stacks". The

smaller the plates are, the more stacks you will needed to create 1 LPM.

Here are some examples, but keep in mind, the size mentioned is the

Active Surface area inside the gasket; the area the water touches.

Gaskets are generally 1/4 to 1/2 inch in diameter, so a 1/2 inch gasket

will require a plate about 1 inch wider:

- 5.5 x 5.5 inch plates only need 1 cell stack ( + n n n n n - )

to produce 1 LPM @ 16 amps

[Current Density is 16.34 amps per cell stack]

- 3.9 x 3.9 need two cell stacks ( + n n n n n - n n n n n + ) to

produce 1 LPM @ 16 amps.

[Current Density is 8.21 amps for each cell stack].

- 3.5 x 3.5 need two cell stacks ( + n n n n n - n n n n n + ) to

produce 829 MLPM @ 16 amps, and 3 cell stacks to produce 1.244 LPM @

almost 20 amps ( + n n n n n - n n n n n + n n n n n -)

[Current Density is 6.62 amps for each cell stack]

- 3 x 3 need two cells stacks ( + n n n n n - n n n n n + ) to

produce 609 MLPM @ 16 amps, and 3 cell stacks to produce 913 MLPM @

almost 15 amps ( + n n n n n - n n n n n + n n n n n -), and 4 cell

stacks @ nearly 20 amps to produce 1.218 LPM

( + n n n n n - n n n n n + n n n n n - n n n n n +)

[Current Density is 4.86 amps per cell stack]

- 2.5 x 2.5 need two cells stacks ( + n n n n n - n n n n n + ) to

produce 423 MLPM @ nearly 7 amps, 3 cell stacks to produce 635 MLPM @

just over 10 amps, and 5 cell stacks to produce 1.059 LPM @ almost 17

amps.

[Current Density is 3.38 amps per cell stack]

Heat Efficiency

All of the above are efficient configurations for 12 volt systems that

can consistently produce HHO while producing minimal amounts of heat.

They all can accomplish the same efficiency as long as their Current

carrying capacity is not exceeded. But do multiple cell stacks heat the

water faster? The answer is yes and no. Lets say one stack is producing

1 LPM @ 16 amps and we add a second stack that also produces 1 LPM @ 16

amps. Both cell stacks are heating the water they share, so yes the

water will heat twice as fast. But a cell stack that produces 2 LPM @ 32

amps will create the same amount of heat as 2 stacks that use 16 amps

each. Perhaps someone smarter than me will create a calculator for

predicting the length of time a cells stack can operate without

overheating the water.

Almost all HHO

Companies over estimate the maximum amperage of their cell stacks

because they don't know how to properly calculate it. For

more details on Current Density , read my article.

|

Improving MMW

Some companies use MMW to calculate the efficiency of their cell stacks.

MMW is the milliliters produced per watt of power, in a minutes time.

Volts time Amps = Watts. I have

already shown you that adding more plates in series increases the HHO

production without increasing the amperage. The MMW of the 7 plate

Series cell, using 12 volts and 16 amps, has a base MMW of 5.208; not

accounting for temperature variations or loses. By adding one more plate

in series, MMW would increase to 6.088. It does so because LPM increases

by 167 MLPM while voltage and amperage remain the same. But you will find

that adding that 8th plate in series increases the resistance between

positive and negative and makes it harder for electrolysis to produce

the gas. The electrolyte mix concentration must be increased in order

to achieve that same amperage. The plate voltage decreases to 1.71 vdc

because another water compartment has formed. If you are using KOH or

NaOH electrolyte, their minimum operating voltage, between the plates, is

1.67 and 1.69 volts respectively. That is barely enough electrical

pressure for electrolysis to take place. That is going to cause a very

slow warm up period. It may take hours for the cell to create enough

heat to conduct well enough to pass 16 amps. That is very very heat

efficient, but it does not make good quantities of HHO on Startup. We

have found that maintaining 2 volts or close to 2 vdc for plate voltage

is the best for long operating times along with good HHO production. As

plate voltage exceeds 2.25 volts, cell operating time decreases. That is why

a 7 plate cell operates 40% longer than a 6 plate cell.

The MMW of a cell stack is affected by voltage changes. Some

companies lower the Operating Voltage from 12 volts and 10 amps, to 10

volts and 10 amps. They then calculate the MMW and tell you it is over

unity. Leave their web site. They are trying to scam you into believing

their product has superior MMW efficiency. You are not going to operate

your cell at 10 volts.

The MMW of a cell stack is also affected by temperature changes in the gas

output. As temperature increases, MMW efficiency decreases. The

temperature of the gas is directly affected by the temperature of the

plates, which affects the temperature of the water. And what most

companies that use MMW as the measuring stick do not realize, is that

MMW decreases, the longer the Cell Stack operates. Current Density has more influence on heat than plate voltage. I

encourage you to study my articles on

MMW and

Current Density. Conclusion

HHO Generators come in various shapes and sizes. Most companies

started their business by building a single small Cell Stack, using

small electrode plates; they fit into smaller places. As demand for more HHO increased, they started adding

multiple individual Cell Stacks in order to make more gas. Someone

eventually came up with the idea of combining Cell Stacks; by sharing

common electrodes and sharing the same water and bubbler. Most companies still use a single

plate size and design. It lowers their cost of production. They only

need one size of plates, and one size of gaskets. They only have to

change the length of the bolts and sometimes the size and shape of the

end plates. So before you invest in an HHO Generator, make sure the

Cell's dimensions

will fit your application. If you need a lot of HHO gas, use as few Cell

Stacks as you reasonably can. 6x6 inch plates can handle about 16 amps.

7 plates in Series can produce 1 LPM @ 16 amps; and do it efficiently.

4x4 inch plates needs 4 Cell Stacks of 7 plates in series in order to

make 1 LPM @ 16 amps. 4x6 inch plates need 2 Cell Stacks of 7 plates in

Series to produce 1 LPM @ 16 amps. Don't forget we calculate current

density by the size of the space inside the plate gasket. Something to

think about.

I hope this article helps you. I wrote it specifically to point out

short comings of most HHO companies out there. Some don't want to tell

you any details about their Cell Stacks; some will tell you anything to

make a Sale; very few will tell you everything.

I figure that if I educate the buyer, they will ask the companies for

more details, and perhaps the companies will clean up their acts. And,

there is always the chance that a Company will read this information

and learn something.

|

|

Comments can be sent to:

mailto:david@hho4free.com |

|

|

|

|

|

|

|

|

|

|

|

|